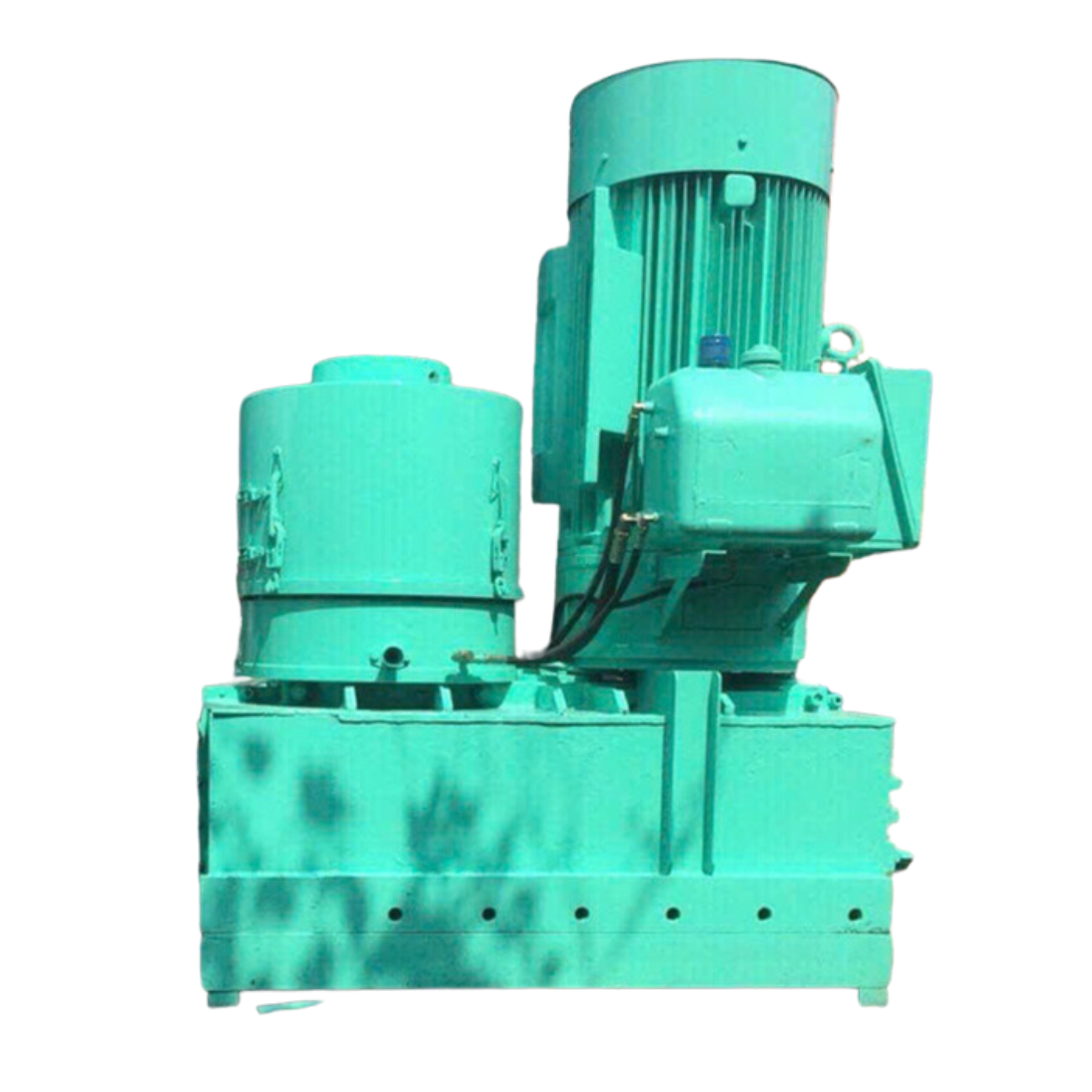

The pellet manufacturing industry is increasingly developing, requiring machines to operate continuously and effectively. However, harsh working conditions can easily lead to rapid wear and tear of components such as bearings and belts, causing production disruption and increased maintenance costs. Choosing quality bearings and belts is a decisive factor in the longevity and performance of the machine.

Performance problem

Maintenance costs

For wood pellet production industry. The part that operates most harshly is the roller. In this case, bearings play the role of bearing all the compressive force and temperature. This is also a part that is replaced frequently and is quite expensive during machine maintenance and repair. Therefore, to reduce costs, some factories have chosen medium quality products for this important part. In fact, when using cheap bearings, it means a short lifespan, leading to the number of times the production unit has to stop the machine for replacement and maintenance more frequently.

The number of replacements is more than per year. Not only does it lead to unreduced maintenance costs, but it also directly affects the annual output per machine.

Các dòng máy nén viên thông dụng

Minimize machine downtime

Optimize performance

With more than 13 years of experience in the field of bearings, Kien Thanh Tin has launched a product group of tapered roller bearings with code ranges from 32220 to 32228 under the KYO brand. Extends lifespan by 30% compared to conventional product lines.

The KYO tapered roller bearing brand for pellet machine rollers has been proven effective and experienced and trusted by more than 20 wood pellet and rice husk pellet producers across the country.

Together

We grow

Kien Thanh Tin has been providing bearing solutions that optimize production costs for more than 20 wood pellet and rice husk factories across the country. We always maintain the desire to accompany and develop with quality products and professional services. Contact us to receive a free consultation and quote now.

Contact us

All of your personal information will be kept completely confidential by Kien Thanh Tin according to the Privacy Policy