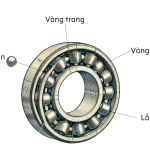

Wood, Sawdust, and Rice Husk Pellet Machines are essential equipment in the biomass energy production industry. Their performance and lifespan greatly depend on the quality of components—among which bearings play a critical role. Bearings are responsible for reducing friction, allowing shafts to rotate smoothly and reliably, ensuring continuous and stable production.

Kien Thanh Tin specializes in supplying industrial-grade bearings, particularly those used in biomass pellet machines. With trusted brands like Win and Kyo, we are committed to delivering high-quality products that meet both technical standards and cost-efficiency requirements.

Why Are Bearings Important for Wood Pellet Machines?

- Reduce Friction, Improve Efficiency: Bearings reduce friction between moving parts, allowing the machine to operate smoothly and save energy.

- Extend Machine Lifespan: High-quality bearings help extend the life of other machine components, minimizing maintenance and repair costs.

- Ensure Product Quality: Stable bearing performance helps pellet machines produce consistently high-quality pellets.

Common Bearing Models Used in Wood Pellet Machines

Depending on the machine type and origin, different bearings may be used. Below are some commonly used bearings in wood pellet machines:

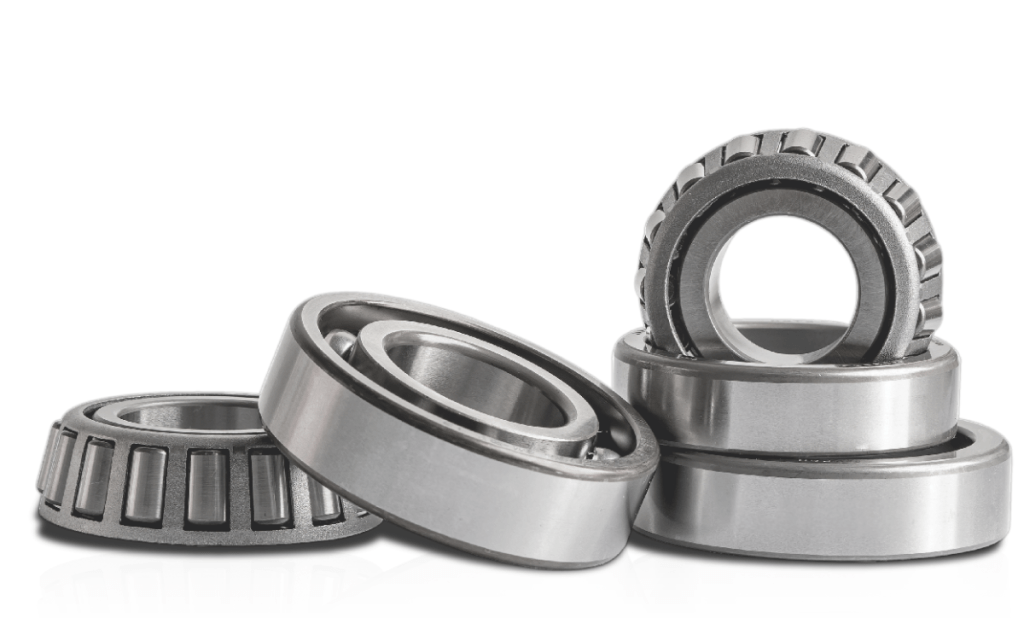

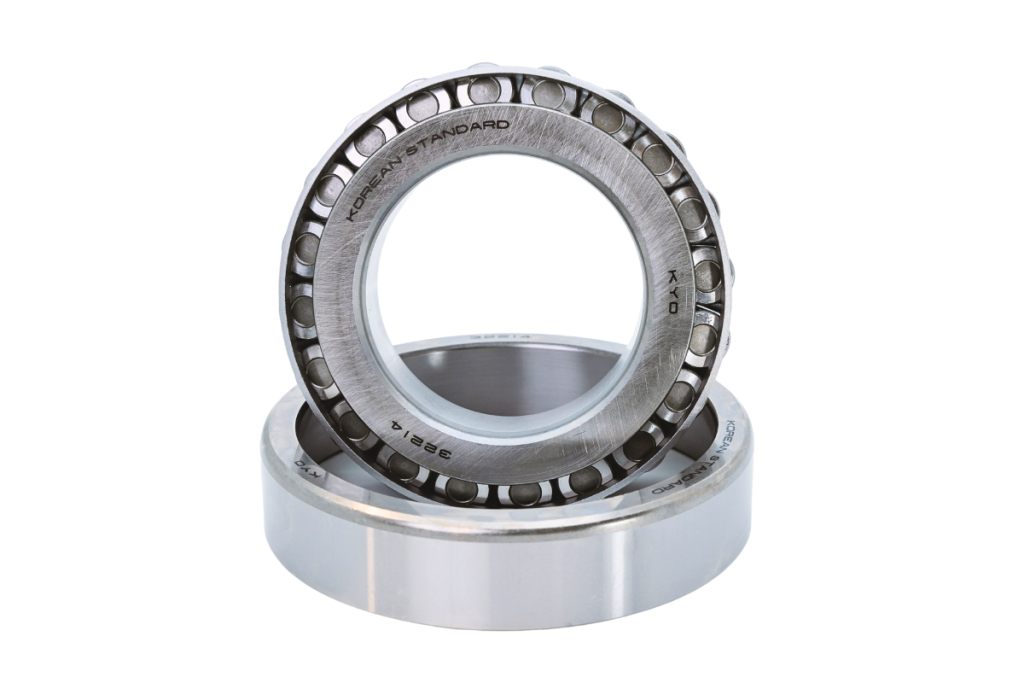

- Bearings for Rollers: 32222; 32224; 32226; 32228; 30322; 30324; 32321; 32230; NJ2222M; NJ2224M; NJ2330M… Among these, the most frequently used bearings for rollers are tapered roller bearings with codes starting with 3xxxx.

Some Common Roller Bearing Models for Pellet Machines

- Thrust Bearings for Vertical Shaft Machines: 29434M; 29440M; 29444M; 29448M; 29452M; 29456M…

Among these, thrust bearings with codes starting with 29xxx are commonly used for vertical shafts that bear upward axial loads.

Một số mã vòng bi cho máy trục đứng

-

Bearings for Gearboxes and Wood Chippers, Pillow Blocks for Conveyors, etc., including:

-

Wood Chippers: 22xx; 23xx

-

Pillow Blocks: UCP3xx; UCF3xx; UCT3xx; UKP3xx; UCFL3xx

-

How to Choose the Right Bearings for Wood Pellet Machines

-

Identify the Machine Type: Each type of wood pellet machine (vertical shaft, horizontal shaft, biomass pellet press) has different structures and bearing requirements. For example, vertical shaft machines often require bearings that can withstand high radial loads, while horizontal shaft machines may need bearings designed for combined loads.

-

Determine the Installation Position: Each bearing position on the machine is subject to different loads and working conditions. For instance, bearings installed on the main shaft typically endure higher loads compared to those on the transmission shaft.

-

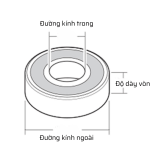

Assess Load and Rotational Speed: The load and rotational speed of the shaft will determine the appropriate size and type of bearing to use.

Kien Thanh Tin – Trusted Supplier of Genuine Bearings for Wood and Rice Husk Pellet Machines

Kien Thanh Tin is one of the leading suppliers of high-quality bearings for wood and rice husk pellet machines in Vietnam. With 13 years of experience in the bearing industry and a network of over 400 partners nationwide, we are committed to:

-

Genuine, high-quality products that help optimize your operation and maintenance costs.

-

Extensive inventory: Kien Thanh Tin stocks over 2,500 SKUs and operates a 3,500 m² warehouse, ready to meet every demand for bearings and belts across the market—with stable and competitive pricing for our partners.

-

Attractive discount policies based on order volume.

-

Dedicated support from an experienced team of consultants and engineers.

Liên hệ với chúng tôi

Over the past 13 years, we have distributed leading brands such as Win, Kyo, NTN, and Taka bearings to more than 400 partners nationwide. Contact us today to explore partnership opportunities. All personal information you provide will be kept strictly confidential.

Conclusion

Bearings play a crucial role in ensuring the performance and longevity of wood pellet machines. Proper selection and maintenance of bearings are key factors that determine the success of the biomass pellet production process.

Kien Thanh Tin is proud to be a trusted partner in the bearing supply industry. Contact us today for professional consultation and dedicated support.

VI

VI